- 421, Qutab Plaza, DLF Ph-1, Gurugram

- info@metalsaws.net

- +(91)9717793539

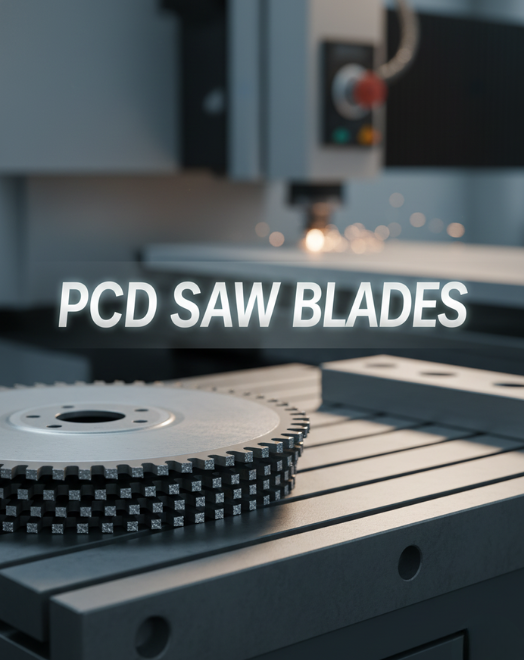

DIAMOND LINE saw blades are tipped with tips made from polycrystalic diamonds (PCD). Used to cut material like Coated and uncoated chipboards, coated and uncoated MDF, and various solid plastic materials.

PCD (Polycrystalic Diamond) Saw Blades are specially designed with tips made from polycrystalic diamonds. These blades are used for cutting a variety of non-ferrous and composite materials.

Diamond Tips: Tipped with tips made from polycrystalic diamonds (PCD) for extreme hardness and wear resistance.

Durable Construction: Provides a long service life and maintains a sharp edge for extended periods in demanding applications.

Accurate Cutting: Ensures clean, precise cuts on specialized panel and plastic materials.

Optimized Geometry (Inferred): Designed to efficiently cut hard, abrasive materials like chipboards and MDF.

Ideal for use in woodworking and plastic fabrication industries for cutting the following materials:

Coated and uncoated chipboards

Coated and uncoated MDF

Various solid plastic materials

Tipping Material: Polycrystalic diamonds (PCD)

Usage: Panel sizing, scoring, and general cutting of composites.

Extended blade life and significantly reduced downtime compared to carbide blades.

Energy-efficient cutting performance due to reduced friction.

High productivity with consistent, high-quality cut on abrasive materials.

PCD Saw Blades (Polycrystalline Diamond) represent the pinnacle of cutting technology, engineered for manufacturers who demand exceptional longevity, precision, and efficiency when working with highly abrasive materials. Unlike traditional Tungsten Carbide (TCT) blades, our DIAMOND LINE blades are tipped with genuine Polycrystalic Diamonds (PCD)—a synthetic, super-hard composite that delivers unmatched wear resistance. This diamond-tipped technology allows the blade to maintain a sharp, clean cutting edge for a lifespan that can be 50 to 100 times longer than conventional tooling, drastically reducing downtime and lowering your cost per cut. Ideal for high-volume applications on demanding materials, including Coated and uncoated chipboards, coated and uncoated MDF, and various solid plastic and composite materials, our PCD blades ensure a consistently clean, chip-free finish every time. Choose PCD for ultimate durability, superior quality, and a massive boost to your production profitability.

Providing sawing solutions since 1998 with trusted precision and performance.

Circular Saws India – your reliable partner for cutting excellence.

Copyright © 2026 All Rights Reserved.